Product

Address: 1013 Hyatt tower, No.8, Yangxia Avenue, Xinqiao community, Xinqiao street, Bao'an District, Shenzhen City, Guangdong Province, China

Tel:86-0755-27260355

Fax:86-0755-27260308

Business hotline: Mr. Zhang13392839815 / 18922803896

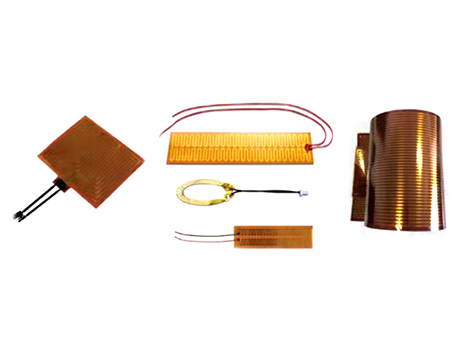

Fever Tablet

Polyimide alloy heating plate点击下载

Introduction

summary:

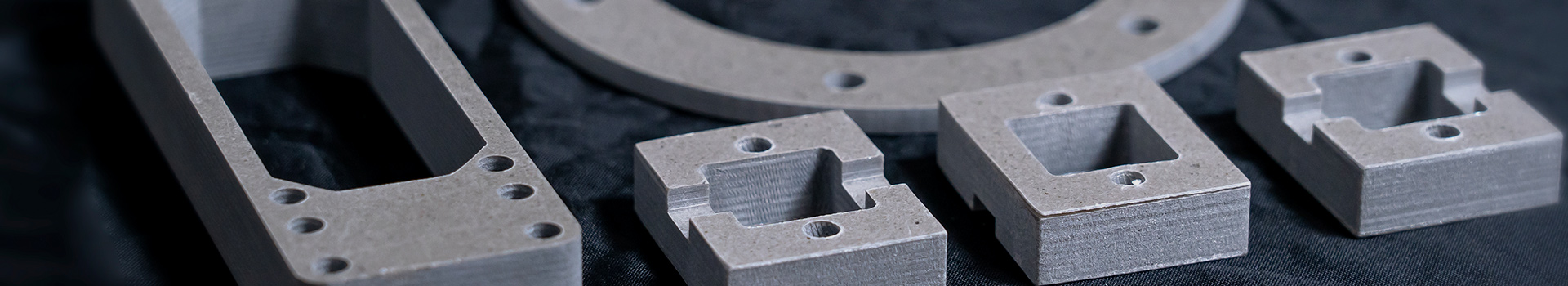

Polyimide alloy heating plate is a thin layer element with certain thickness composed of the electro positive chip and the polyimide film insulation carrier. The heating plate is made of nickel lattice alloy foil which is coated on the polyimide, which is a high temperature resistant insulating carrier, and then pressed by polyimide film. Polyimide alloy heating plate is thin, light and flexible, can be in full contact with the heated object, can let the heat transfer to any place needed, improve heat transfer in the treatment, accelerate heating and reduce power needs.

characteristic:

-

precise heating: the heating plate can be heated almost anywhere needed. The heater can be pasted on the surface of the heating piece. The heater with high heat flux density can be customized where the heat loss is large: the heat is even. The element is flat, and the effective coverage of the heat receiver is high (up to 90%), so the heating is uniform and the heat loss is small: the heater starts quickly and has good efficiency, The conversion rate of electric heating is 98%;

-

fast preheating speed: the plate foil element has a larger effective heat conduction area than the wound heating plate. There is a small temperature gradient between the heating plate and the heat sink, so the heater keeps a lower temperature, so it allows the high heat flow density to be generated. The heating plate can work with the heat flux density of the winding heater twice as much as that of the coil heater;

-

space saving and weight reduction: the heating plate usually weighs only 0.023-0.037 g/cm, and the thickness is only 0.09-0.14 mm; For the narrow space applications, such as portable instruments, high-precision electronic equipment: heating plates can be bonded to specific places, or fixed by clamping, hook, press button, hole fixing, etc., and can also be directly pasted with the heating parts needed;

-

The heater is suitable for various kinds of special heating. The place where bending and heating is needed is flexible and can be used for ring wrapping and bending, and can be installed on different heating bodies;

-

corrosion resistance and moisture resistance. Because the heating plate is wrapped by the insulation material which is resistant to temperature, it can avoid being damp and corroded; The heat dissipation area of the components is large, and there is no open fire (working temperature ≤ 180C) and ultra high temperature area during operation: the carrier and packaging materials are made of positive combustion materials, and the use is safe;

-

the positive temperature coefficient characteristic heater has the characteristics of high temperature, lower power, and high power, fast temperature compensation, and self limiting temperature characteristics: good temperature control. Because the thermal resistance and thermal inertia of the components are relatively small and the temperature response is fast, the temperature is easy to control and can be used for fine constant temperature control;

-

the temperature range of heating plate is from 30 to 180C, and the maximum power load can be provided is 3.0w/cme (forced cooling, the heating plate is very thin, the heat transfer effect is good, and the actual heating temperature is very close to the workpiece: the heating element is of sheet structure, which provides more uniform heat field than the traditional filament element. The heating time is short and the response speed is fast, and the power load is lower than that of the traditional filament element;

-

pressure sensitive adhesive can be used to bond flat and smooth workpiece; The maximum temperature of pressure sensitive adhesive is: 180C for 220c;

-

silicone rubber heater coated with pressure sensitive adhesive should be used within half a year after factory delivery, otherwise it will affect the use performance of glue;

-

the temperature controller and fuse can be directly covered on the outer surface of polyimide alloy heating plate, and it is safe and convenient to use.