Product

Address: 1013 Hyatt tower, No.8, Yangxia Avenue, Xinqiao community, Xinqiao street, Bao'an District, Shenzhen City, Guangdong Province, China

Tel:86-0755-27260355

Fax:86-0755-27260308

Business hotline: Mr. Zhang13392839815 / 18922803896

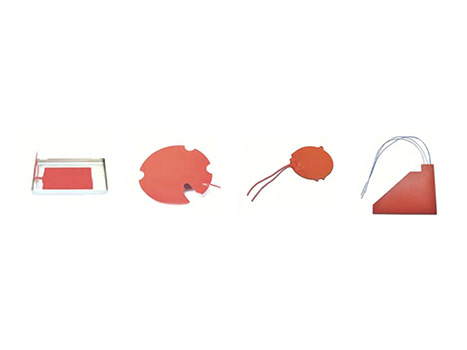

Fever Tablet

Silicone rubber heating plate点击下载

Introduction

The silicon rubber heating sheet is mainly composed of Ni Cr alloy electric hot wire and high temperature insulating cloth of silicone rubber. The silicon rubber heating sheet is made of nickel chromium alloy hot wire or nickel Ming alloy foil wrapped or coated on the high temperature resistant insulating carrier, and then pressed by double layer silica gel at high temperature. The heat transfer effect of silicone rubber heating sheet is good, the weight is light and flexible. The actual heating temperature is very close to the workpiece, and can be in close contact with the heated object, so as to make the heat transfer to any place needed, improve the heat transfer in the treatment, accelerate the heating up and reduce the power demand.

characteristic:

-

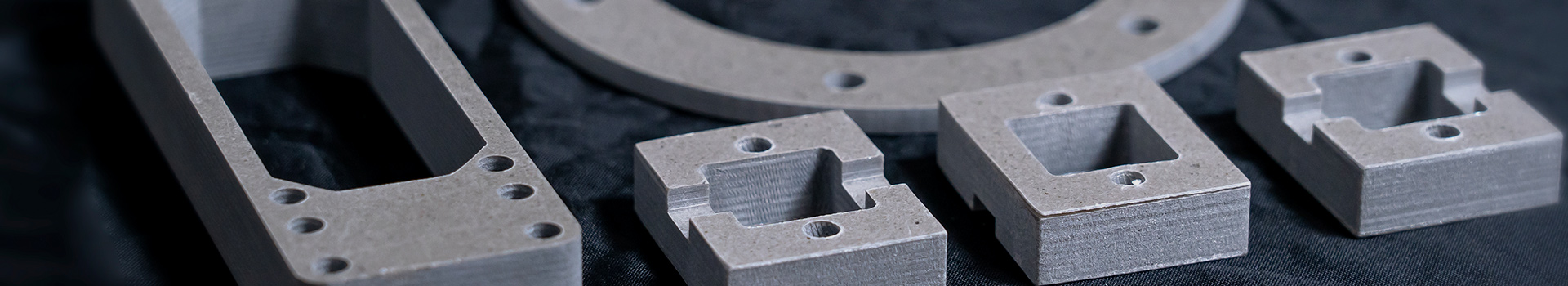

heater can be made into other heterogeneous products, shapes and patterns such as ring plate;

-

it is very convenient to install, such as room temperature vulcanization adhesive, vulcanization installation, mechanical fixing hole installation, or binding port installation;

-

it has good anti lake, good waterproof performance, uniform temperature and chemical corrosion resistance. Good toughness and UV resistance. Anti aging. Acid alkali resistant, longer heater life than other materials;

-

the positive temperature coefficient heater has the characteristics of self limiting temperature. The higher the temperature, the smaller the power is, on the contrary, the power is large and the temperature compensation is fast;

-

the element provides more uniform heat field than the traditional filament electric heating element, with short heating time and fast response speed. Compared with traditional filament electric heating element, the power load is low and the service life is longer;

-

pressure sensitive adhesive can be used to bond on flat and smooth workpiece: the maximum temperature of pressure sensitive adhesive is 150C continuous and 180C instant; Power density;

-

silicone rubber heater coated with pressure sensitive adhesive should be used within half a year after delivery, otherwise the use performance of glue will be affected;

-

the temperature controller and fuse can be directly buried in the middle interlayer of silicone rubber heater, which is convenient to use;

-

the continuous operating temperature shall be less than 180C and the instantaneous temperature shall not exceed 200C; Under the working and pressure condition, the auxiliary pressing plate is used to make it close to the heating surface, and the heat conduction is good. When the temperature of the working area is not more than 200C, the current density can reach 3w/cme; Under the installation condition of adhesive type, the allowable working temperature is ≤ 150C; If the air is dry burned, the power density shall be ≤ 1 w/cm2; The power density can reach 1.5 w/cme under non continuous condition.